For small-scale edible mushroom growers—particularly those operating on less than five acres or experimenting on a small plot—the right equipment can significantly boost efficiency and reduce labor...

2025-05-10 Read More

From October 4 to 6, 2024, Satrise participated in the India Mushroom Days 2024. At the India Mushroom Days 2024, Satrise became a beautiful sight with its professional mushroom cultivation equipm...

2024-10-05 Read More

In the world of edible mushroom production, the quality of the substrate directly influences the final yield and health of the crop. Properly mixing the substrate—comprising various organic compone...

2023-04-17 Read More

As a manufacturer of mushroom cultivation equipment, we specialize in providing efficient and intelligent climate control systems to address the challenges posed by changing weather conditions in m...

2022-08-25 Read More

The factory production of shiitake mushrooms mainly includes the following steps: stick making, sterilization, cooling, inoculation, cultivation and fruiting. 1. Mixing and Bagging In the stick ma...

2021-07-25 Read More

Recently, a food giant based in Los Angeles announced its active exploration of a new type of mushroom as a substitute for poultry. This mushroom is not only rich in nutrients but also has a taste ...

2020-08-25 Read More

1. Temperature The nameko mushroom genus is cold-tolerant, thriving best in conditions of 10-15°C. It can grow at around 5°C, but not vigorously. Growth slows above 20°C, leading to smaller caps, t...

2019-10-25 Read More

In the edible mushroom industry, solid spawn has traditionally been the preferred choice due to its relatively simple production process and lower equipment requirements. However, solid spawn comes...

2018-12-15 Read More

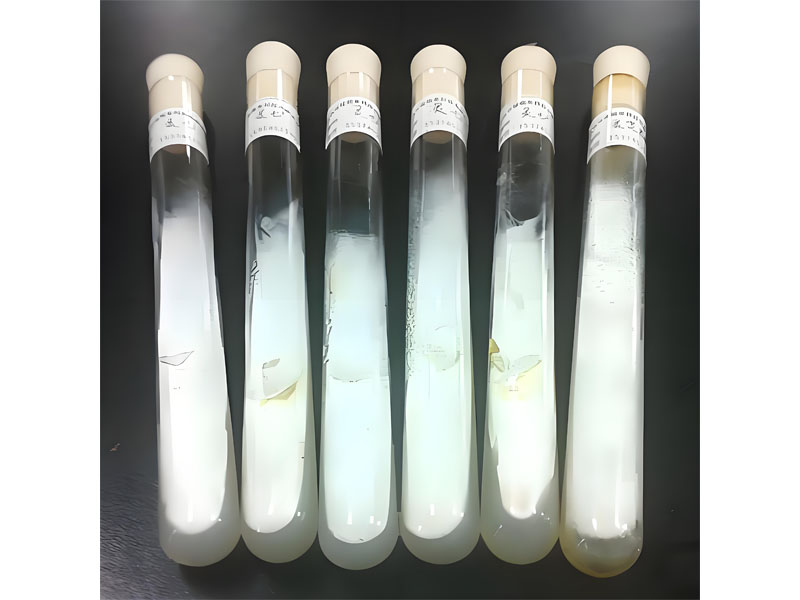

Like solid spawn, liquid spawn for edible mushrooms is also classified into three levels: Master Spawn (First-Level Spawn): Cultured in test tubes or petri dishes. Intermediate Spawn (Second-Level...

2018-02-15 Read More

Product Category